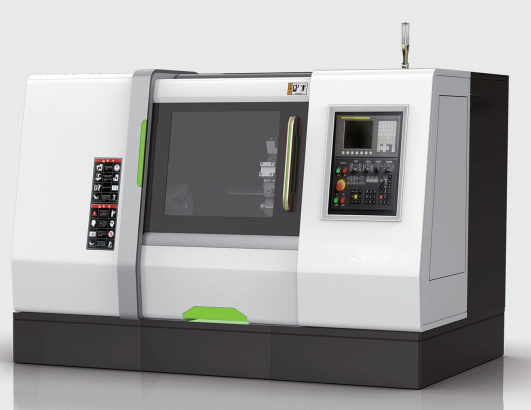

HCK6163-1000 Skew Rail CNC Lathe

Couldn't load pickup availability

HCK's CNC tilting lathe is a high and low-speed two-stop mechatronic processing machine tool, a programming input can automatically realize the machining of mechanical parts of the outer circle, inner hole, threads, complex curved surfaces, which is widely used in machinery, automobiles, motorcycles, oil pumps and nozzles, chemical industry, instrumentation, medical care and other industries for mechanical processing of parts.

Main structural features

1、Horizontal flat bed structure, bed and bed base and other major components are made of high-strength materials, resin sand casting, full aging treatment, guideway by high-frequency quenching treatment, to ensure the stability of the machine tool for long-term use, X, Z direction of movement of the guideway vice paste plastic treatment is durable.

2, the spindle is stepless speed regulation: the speed is 50-3000 r/min, the front bearing of the spindle system adopts double-row cylindrical roller bearings, and the rear bearing adopts high-precision, high speed angular contact bearings, which has the characteristics of high speed, high precision, high rigidity, small thermal deformation, smooth operation, low noise, and so on.

3. The vertical and horizontal motion axes of the machine tool are driven by servo motors and driven by precision ball screws with fast response, high precision and long life. The screw bearings use special angular contact bearings for screws with a contact angle of 60°, which can withstand high axial loads and ensure the rigidity and precision of the feed transmission device.

4、Standard configuration for domestic brand name vertical four-station electric tool holder and ordinary chuck.

5, can be configured according to user requirements of hydraulic, electric, pneumatic chuck and hydraulic, pneumatic tailstock.

The machine tool adopts double-door semi-protection design, which is convenient for operation and reliable for waterproof and chip-proof.

| Main Technical Parameters | HCK6163-1000 |

| Bed And Horizontal Inclination | 45°/55° |

| Span Of Guideway | 640mm |

| Max. Bar Diameter | 630mm |

| Max. Rotary Diameter | 350mm |

| Max. Diameter Of Passing Plate | φ580mm |

| X,Y,Z Axis Travel | 350mm*90mm*100mm |

| X,Z Rapid Traverse Speed | 16/16min |

| X,Z Ball Screw | 40*10 C2 50*12 C3 |

| Spindle End Type | A2-8 |

| Spindle Through-Hole Diameter | φ105mm |

| Hydraulic Chuck | 10inch hydraulic |

| Diameter Of Tailstock Center Sleeve | φ100mm |

| Turret Typ | Servo-Powered Turret |

| Spindle Speed | 2500rpm |

| Spindle Taper Hole | CJL340 |

| Spindle Power | 15kW |

| Turret Capacity | 12stations |

| CNC System | Fanuc/Siemens/Mitsubishi/Syntec/Knd |

| Positioning Accuracy | 0.005mm |

| Repeat Positioning Accuracy | 0.003mm |

| Machine Size | 4000mm*2200mm*2600mm |

| Machine Weight | 6.5t |